Building an Effective Hose Maintenance Framework

Maximising Hose Performance: Essential Steps for Industrial Operations

Unexpected hose failures can bring industrial operations to a standstill, leading to costly downtime and safety hazards. A well-structured maintenance strategy is essential to prevent these issues, ensuring hoses are replaced before wear and tear compromises performance.

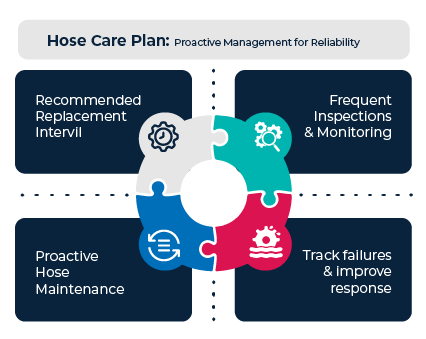

At IFPP, we advocate for a proactive approach to hose management because tracking individual hose performance and making data-driven decisions can significantly improve operational efficiency.

Key Considerations for Hose Longevity

Hoses operate under diverse conditions, and their lifespan varies depending on several factors, including pressure, fluid type, environmental exposure, and mechanical stress. Businesses should assess real-world conditions to determine optimal maintenance schedules.

For example, hoses in high-temperature environments degrade faster than those in controlled conditions. A rigid maintenance schedule that doesn’t account for these differences can lead to premature failures or unnecessary replacements, both of which drive up costs.

The IFPP Solution

To keep industrial hoses in top condition, companies should implement a structured maintenance process with the following steps:

1. Comprehensive Hose Inventory & Identification

Start by cataloguing all hoses in use, documenting key details such as size, material, compatibility, pressure capacity, and environmental conditions. Assigning each hose a unique identifier ensures seamless tracking and simplifies future reordering.

2. Routine Inspections & Performance Monitoring

Schedule regular hose assessments to check for visible signs of degradation, such as cracks, bulging, or abrasion. Keeping detailed inspection logs allows engineers to detect wear trends and refine replacement schedules based on actual performance rather than estimated timelines.

3. Reducing Exposure to Stress Factors

Evaluate operational conditions to identify potential stressors affecting hose performance. Addressing issues such as improper routing, excessive bending, or proximity to heat sources can extend the lifespan of hoses and prevent premature failures.

4. Implementing Protective Measures

Some environments require additional safeguards to maintain hose integrity. Heat-resistant sleeves, UV shielding, and abrasion guards can help mitigate external damage, reducing the frequency of replacements.

5. Data-Driven Adjustments to Maintenance Schedules

Rather than replacing hoses on fixed intervals, analyse past performance data to make informed maintenance decisions. If certain hoses exhibit higher failure rates, switching to a more durable alternative or adjusting replacement frequency can optimise longevity and cost-efficiency.

Why a Proactive Maintenance Approach Matters

Industrial facilities that implement structured hose maintenance strategies experience fewer unexpected failures, improved safety, and reduced downtime. By investing in proactive monitoring and replacement planning, businesses can minimise operational disruptions and enhance equipment reliability.

Get Expert Support from IFPP

Need help setting up a tailored hose maintenance program? IFPP provides expert guidance, free hose audits, and high-quality industrial hose solutions to support your operations.

📧 Contact us at: sales@ifpp.co.uk

📞 Call us on: 0113 289 0281